Production Process

In Gunma Prefecture, where our workshop is located, creative kokeshi dolls by various artists are made.

Creative kokeshi dolls are known for their diverse shapes and non-traditional designs, but

many of them are compatible

with Japanese landscapes and traditional Japanese-style rooms, providing an opportunity to appreciate

Japanese

aesthetics even for those living overseas.

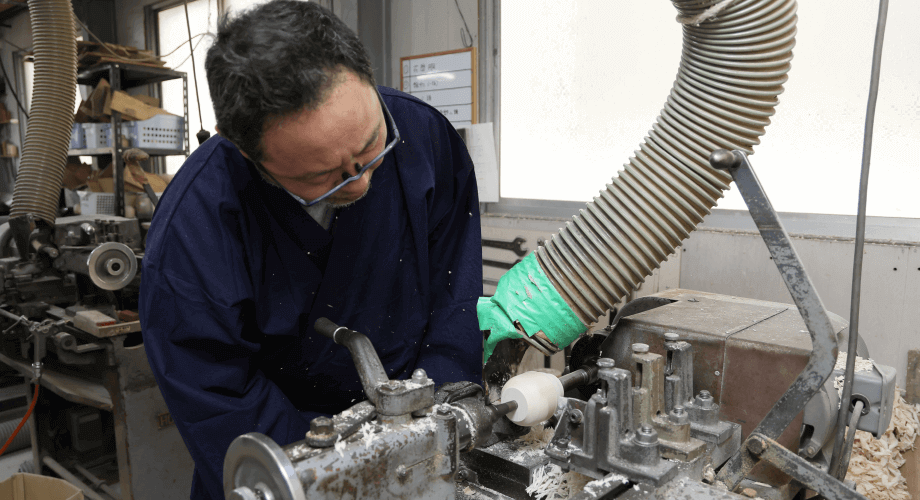

Our craftsmen respond to each request with care.

Manufacturing process

01

Drying

Mizuki, a commonly used material for kokeshi, is processed by peeling off the bark of freshly harvested trees by hand and naturally drying them for one to two years until the wood reaches an appropriate level of dryness and whiteness for making kokeshi dolls.

02

lumbering

Length are determined and knots are removed.

03

polishing

Three stages of polishing are performed: rough polishing, base polishing, and finishing polishing. After the design is burned or carved onto the surface, it is painted with two base coats and one finishing coat.

04

painting

After the design is burned or carved onto the surface

05

coating

it is painted with two base coats and one finishing coat.

06

assembly

Finally, the kokeshi doll is assembled to complete the process.